In today's video, I highlighted industrial Raspberry Pi computers. Specifically, the Lincoln-Binns CM4-Box Pro, the Onlogic Factor 201, and fieldcloud's Milü-X Industrial IoT Gateway.

And I asked Lincoln-Binns, Onlogic, and fieldcloud what makes an 'Industrial' Pi any different than a Pi and an enclosure like you could buy from a normal Pi retailer.

After all, even accounting for custom Compute Module 4 carrier boards, there are dozens of similar options for less than a hundred bucks. Why does the Factor 201 I reviewed cost over $500? And why is the Milü-X—which can't be bought standalone—so expensive that fieldcloud doesn't list the price?

The answer is any industrial computer—whether Raspberry Pi-based or X86, or whatever—has to go through much more rigorous testing, and has to run in vastly different environments than your run of the mill hobby board you'd run in your home or office.

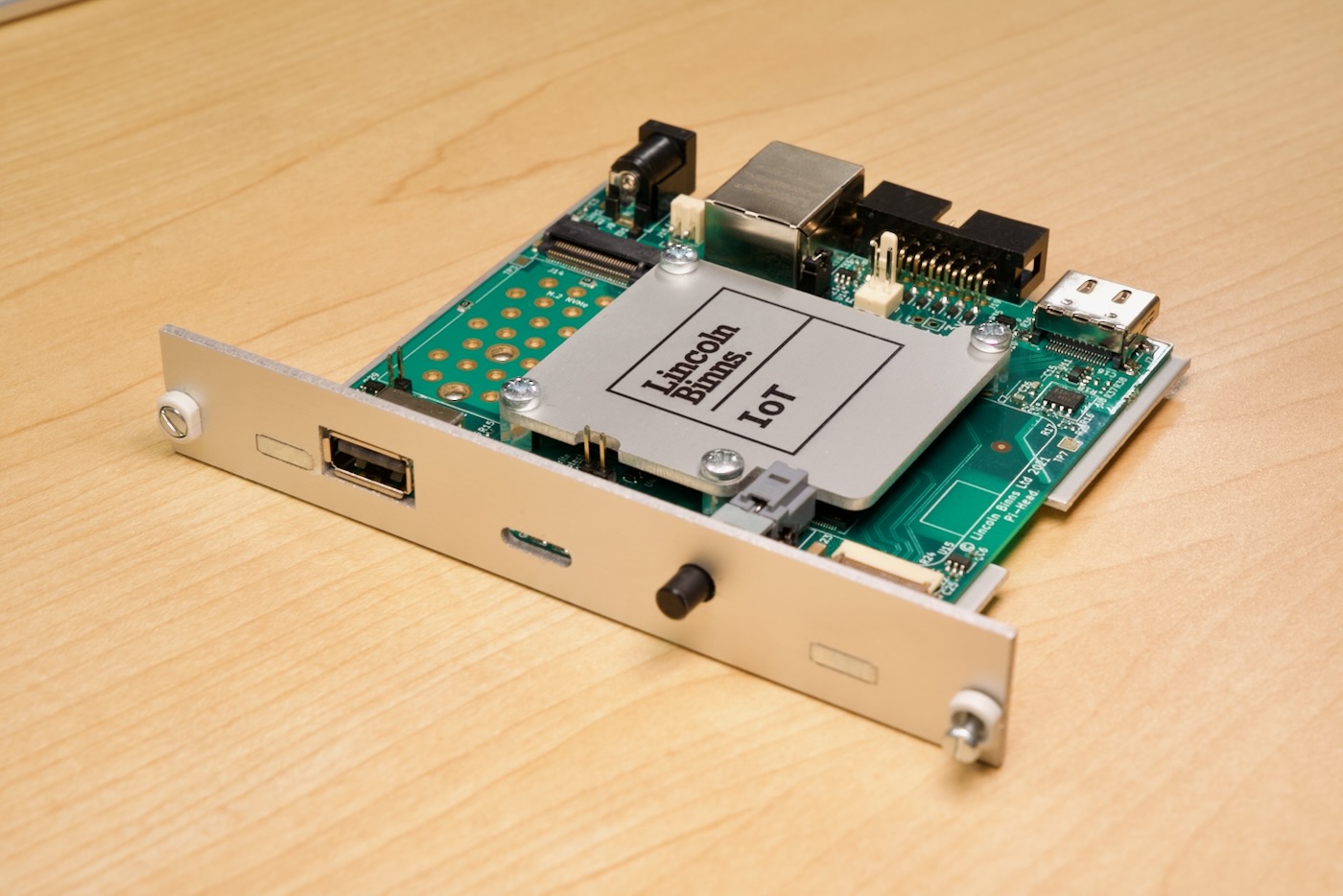

And like the board pictured above—a eurocard mount for Lincoln-Binns' board—they are often built to be mounted in unique configurations, whether DIN rail, VESA, standalone, or in something completely custom, like the Milü-X's enclosure, which is certified for use in highly explosive environments like oil refineries, flour mills, mines, and pharmaceutical plants:

Watch the video to learn more about these Industrial Pi computers—and why they're so expensive:

Comments

I'm not registered on youtube, so I'll comment here:

All the people complaining that they cannot get hold of a Raspberry PI, as all 500k/month are going to industrial and commercial customers, consider this:

Those customers will have made firm commitments to buy X units a month, for say 24 months. They might even have paid for some of the production up-front.

In return Raspberry PI Trading, will have also signed the contract to supply X units/month at Y cost, for 24 months.

Thus of the 500k/month production, the first units will go to the contracts with firm commitments.

The next will go to the contracts without firm commitments, (or some agreed percentage, if stock is short)

Finally, the rest will go to distributers for sale.

The R-PI foundation is not "Forgetting" it's education and maker customers, it's just got to meet it's contracted requirements, first.

The above will apply across the whole electronics supply chain.

Broadcom, who makes the CPU in the PI, will have firm commitments to it's large customers, who use the CPU in smart TVs, and Set-Top-Boxes. Any left over will go to the rest of their customers, including the Raspberry Pi foundation.

The same applies to memory chips, flash, network controllers, even voltage-regulators and leds.

Nvidia had problems with GPU shortages. Nvidia does not have their own chip manufacturing plant, they use someone else's.

When the industry started back-up after lockdown, production was slow to start, and any manufacturing capacity went to their firm contracts.

Nvidia would not have been as big as some of the others, so they had less capacity given to them.

The GPUs that were made, went to 3rd party board manufacturers, and also to Nvidia's own board production.

The crypto miners will have been able to commit to buying X GPUs / month, and likely paid up-front.

So the production went mainly to crypto miners, either through commitments to supply finished cards, or by 3rd parties buying GPU chips to make boards.

That is nothing to do with "fairness" or "not being loyal to gamers", and everything to do with trying to meet their commitments, and honour their contracts with customers. It's just basic business.

Gamers and enthusiasts / makers, and a small, but profitable part of the whole I.T / electronics industry.

The biggest customer gets to call the shots, and it isn't us, the hobbyist.

Hey jeff, great video as always (i'm a bit late on this one...). I love your shirt by the way, could you give me a hint on how to get one (the black with all pi's) I just could not find it...

Keep the great work !